If you buy one of the ready-to-drink energy or vitamin drinks in the assumption that it will give you the necessary kick, you might be in for a surprise. The kick is not coming and you discover you just drank a very sweet soda, nothing more. Well, sugar of course gives some extra energy, but the expected dose of vitamins might not have worked.

If you buy one of the ready-to-drink energy or vitamin drinks in the assumption that it will give you the necessary kick, you might be in for a surprise. The kick is not coming and you discover you just drank a very sweet soda, nothing more. Well, sugar of course gives some extra energy, but the expected dose of vitamins might not have worked.

Deterioration of vitamins and nutrients

It is generally known, that most vitamins and other nutrients are very sensitive and lose their power the moment they get mixed with a liquid, particularly water. In other words they start deteriorating the moment the bottle leaves the filling line. The longer they stay mixed, the less efficiently vitamins and nutrients work. Vitamin C, for example, loses 80% of its potency after only 30 days.

It is even worse, as beverage companies add flavouring to make their product more attractive to the consumer. Most added flavours are fruit additives, and if they are natural, the beverage degrades if stored at ambient temperatures for a prolonged period of time.

Shelf-life can be broadly defined as the length of time between initial packaging of a product and the point at which consumers notice a decrease in product quality. Thus, shelf-life of a product is determined by the least stable aspect of that product or its package. For moderate to high acid-containing citrus beverages, in other words most fruit additives, the least stable aspect, as well as the cause of greatest flavour degradation, is the extended contact of the favouring extract with water.

Functional Bottle Caps

Various companies marketing energy and vitamin drinks have developed solutions for this problem. In the past I wrote about several of them, the VIZcap, the Activate, the Cedevita and the Delo cap, that keep the vitamins dry and fresh until consumption of the drink. See my article “Innovative dispensing bottle caps for sensitive vitamins“.

But ingenious or not these dispensing caps, or functional caps, as they are sometimes called, have all one problem. Except for the Delo cap, all dispensing caps are proprietary of the drinks company, which limits the possibilities of wider implementation in the market for energy and vitamin drinks.

Developing a functional cap is quite an expensive exercise, leaving many an energy drink no other choice than “slowly deteriorating” in its container.

As said, in the end of the day consumers expecting to drink a healthier product don’t get what they actually paid for.

Tap-The-Cap

That all might change in the near future. Tap The Cap Inc., an innovation company in California, developed the (logically) Tap-The-Cap dispensing cap. The patented development solves the problem of many fortified beverage companies as it can be used by any brand. It is not limited to one brand. Furthermore the cap has the special design that it is universal, in other words it can be used as cap filled with vitamins and sold without the bottle with water, as the cap fits almost any still water bottle in the market.

A huge improvement for all consumers, who like to add “value” to their own preferred water brand!

To use Tap-The-Cap is simple: Remove the (screw) cap of the water bottle, Push the Tap-The-Cap over the neck of the bottle, Tap down on the spout, Shake the bottle, Pull up on the spout and enjoy your drink.

The technique behind the cap of course is a bit more complicated. Let’s have a look at some details.

The technique behind the cap of course is a bit more complicated. Let’s have a look at some details.

In its basics the Tap-The-Cap is like any other dispensing cap as it has to dispense a supplement (vitamins, flavours, nutrients) through a bottle neck opening and into the bottle. However one of the most interesting features of the Tap-The-Cap is its configuration to connect to beverage bottle necks of different sizes.

Bottle necks often have screw threads to accommodate the original threaded cap attached to the bottle. The Tap-The-Cap can be put in place on the bottle neck after the original bottle cap has been removed.

As the exploded view shows the dispensing cap system is designed to seal off the mouth of a beverage bottle.

The cap features a number of fingers, while the distal ends of the fingers have inwardly barbs or tabs, which have sloped surfaces. The fingers are thin and have some flexibility. They are made so long so that the tips of the fingers flex outwardly as the cap is pushed onto the neck of the bottle, and the barbs engage under the extending flange of the bottle neck.

With this design the structure of the cap also accommodates non-threaded beverage bottles, by engaging with the bottle flange or collar, as the fingers and the barbs do not have to match the threads of the bottle neck, which varies with different beverage or bottle types. The design even include an extra tooth on the inside of the fingers which engages with the threads on the bottle neck by sliding over some or all the threads as the cap is pushed onto a threaded bottle neck, and locks in place without rotationally being screwed on the bottle.

A seal is located inside the housing to provide a liquid seal against the neck opening and as it is made from an elastomeric material, it will deform according to the size and design of the bottle neck, compensating for any size difference, while the flexibility of the fingers for their part compensate at the outside of the neck for bottle sizes from 26 to 32 mm.

The supplement storage is of a cup-like design, with a cylindrical sidewall and a membrane. The storage chamber defines the volume of the quantity of a supplement in granular, powder or liquid form. According to the company the storage can hold 9.5 grams, representing 9.5 cm3 (.58 cu inch, .33 fluid oz).

A valve sits in the centre of the storage chamber and is attached to the cap, configured for movement between a closed and a dispensing position, in which passage of the supplement is permitted from the storage into the bottle.

A drinking spout is positioned on top of the valve to allow the bottle content to be consumed. The sidewall of the spout has several ports, which permit the beverage to pass through from the bottle when the valve is in an open position.

When you look at this universal dispensing or functional cap, you must agree that the inventors with their more than 25 years experience in the health and wellness industry, succeeded in their goal, (as they formulated it) “to create a safe and effective way for people to take their supplements without having to swallow a pill or capsule or get taken in by those over-hyped vitamin fortified waters where the vitamins have already deteriorated in the liquid”.

Currently, the inventors are looking to licensing out their technology. Interested parties can contact info@tapthecap.com.

Tagged: beverage bottles, dispensing caps, energy drinks, functional caps, Tap-The-Cap, vitamin drinks

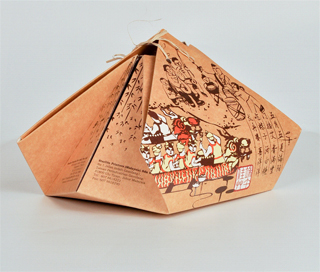

This month we start again our series of new packaging developments. An ingenious packaging format for artisan square sandwiches, Salanova lettuce to grow in your own kitchen, a paperboard handgrenade holding a boxer short, nostalgic paperboard baskets for fruit and vegetables and from Singapore a Rice Dumpling Box made from nostalgic unbleached kraft.

This month we start again our series of new packaging developments. An ingenious packaging format for artisan square sandwiches, Salanova lettuce to grow in your own kitchen, a paperboard handgrenade holding a boxer short, nostalgic paperboard baskets for fruit and vegetables and from Singapore a Rice Dumpling Box made from nostalgic unbleached kraft.

It is shaped just like its content, a rice dumpling, complete with a string. To add to the nostalgia feel, the package is printed on uncoated kraft that brings back memories of the paper bags that were a common sight years ago by simulating the look of the good old brown paper bags.

It is shaped just like its content, a rice dumpling, complete with a string. To add to the nostalgia feel, the package is printed on uncoated kraft that brings back memories of the paper bags that were a common sight years ago by simulating the look of the good old brown paper bags.

In general it can be said that dispensing caps or functional caps are used to store dry or liquid supplements separately from the water in which when released by the consumer they form an energy or vitamin drink or sometimes a medicinal drink, under the assumption or claim that supplements, particularly vitamins deteriorate in water quickly and as such a ready-to-drink vitamin beverage doesn’t give the consumer the kick he/she was expecting and paid for.

In general it can be said that dispensing caps or functional caps are used to store dry or liquid supplements separately from the water in which when released by the consumer they form an energy or vitamin drink or sometimes a medicinal drink, under the assumption or claim that supplements, particularly vitamins deteriorate in water quickly and as such a ready-to-drink vitamin beverage doesn’t give the consumer the kick he/she was expecting and paid for.

In 2009 Rising Beverage Co. in Los Angeles, the owner of Activate, launched a line of functional beverages that features a custom-designed cap to keep vitamins and other healthful ingredients fresh until consumption.

In 2009 Rising Beverage Co. in Los Angeles, the owner of Activate, launched a line of functional beverages that features a custom-designed cap to keep vitamins and other healthful ingredients fresh until consumption.

In contrast to the Activate cap and many others the VizCap isn’t exclusively linked to a drinks company and not even to a specific bottle. The VIZcap, designed by

In contrast to the Activate cap and many others the VizCap isn’t exclusively linked to a drinks company and not even to a specific bottle. The VIZcap, designed by

Sushi, the famous Japanese dish from decorative fresh fish products, has not only to be superb of taste, but it has to be much more. It has to appeal as much to the eye as to the palate. It has to be fresh, perfect of taste and please the eye. In other words the packaging complements the perfection.

Sushi, the famous Japanese dish from decorative fresh fish products, has not only to be superb of taste, but it has to be much more. It has to appeal as much to the eye as to the palate. It has to be fresh, perfect of taste and please the eye. In other words the packaging complements the perfection.

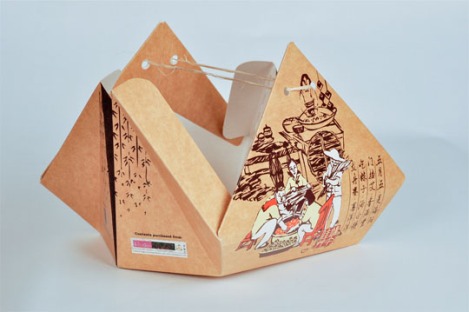

In the same style as the Danish design is the Sta-Pack created by PT Bukit Muria Jaya/BMJ in Indonesia. Not quite the same, as the Sta-Pack consists of several separate units with an added handle. It certainly is a nice and elegant solution as fast food packaging, especially for the take-away market of upscale meals.

In the same style as the Danish design is the Sta-Pack created by PT Bukit Muria Jaya/BMJ in Indonesia. Not quite the same, as the Sta-Pack consists of several separate units with an added handle. It certainly is a nice and elegant solution as fast food packaging, especially for the take-away market of upscale meals.

I wrote about this packaging in a previous article, not long ago, but it is such a beautiful construction that it can easily be adapted to take-out meals.

I wrote about this packaging in a previous article, not long ago, but it is such a beautiful construction that it can easily be adapted to take-out meals.

I seldom write about medical and pharmaceutical packaging. The reason is simple. In my some 45 years of experience in the packaging field, I have been mainly engaged in packaging technology for food packaging and only sporadically and intermediately in non-food applications. Furthermore, and I know a lot of my readers will disagree, I find food packaging much more fascinating and its solutions more complicated, than non-food packaging. Of course pharmaceutical, medical and cosmetic packaging are also very demanding, but their demands arise from rules and regulations, counterfeiting and the like and less from the product requirements.

I seldom write about medical and pharmaceutical packaging. The reason is simple. In my some 45 years of experience in the packaging field, I have been mainly engaged in packaging technology for food packaging and only sporadically and intermediately in non-food applications. Furthermore, and I know a lot of my readers will disagree, I find food packaging much more fascinating and its solutions more complicated, than non-food packaging. Of course pharmaceutical, medical and cosmetic packaging are also very demanding, but their demands arise from rules and regulations, counterfeiting and the like and less from the product requirements. So let me help him a bit to accommodate that answer and highlight some interesting developments in pharmaceutical packaging here. We start with “Talking packaging is the future”.

So let me help him a bit to accommodate that answer and highlight some interesting developments in pharmaceutical packaging here. We start with “Talking packaging is the future”.

Global manufacturer of plastic closures

Global manufacturer of plastic closures

On the

On the

Today the 27th of March the Anuga FoodTec in Cologne, Germany, opened its doors. Scheduled from March 27 to March 30, the Anuga FoodTec offers international food manufacturing companies an opportunity to view the latest technologies dedicated to food and beverage processing, packaging and food safety. The event also includes specialist forums and conference sessions.

Today the 27th of March the Anuga FoodTec in Cologne, Germany, opened its doors. Scheduled from March 27 to March 30, the Anuga FoodTec offers international food manufacturing companies an opportunity to view the latest technologies dedicated to food and beverage processing, packaging and food safety. The event also includes specialist forums and conference sessions.

Within its thermoforming division,

Within its thermoforming division,  My readers might recall that some time ago I wrote about the developments in

My readers might recall that some time ago I wrote about the developments in  Lamican packages consist on several laminated layers, including the pull tape made of aluminium, printing inks and varnish, alufoil, tie layer and LDPE.

Lamican packages consist on several laminated layers, including the pull tape made of aluminium, printing inks and varnish, alufoil, tie layer and LDPE.

Reclosable beverage cans are not new, but this design of

Reclosable beverage cans are not new, but this design of

Lightweighting has proved to be a winning business concept in the liquid food business. Three years ago

Lightweighting has proved to be a winning business concept in the liquid food business. Three years ago

Tetra Pak unveiled four new features for its carton packaging portfolio at Anuga FoodTec, all four aimed at strengthening the environmental attributes of several of its leading products.

Tetra Pak unveiled four new features for its carton packaging portfolio at Anuga FoodTec, all four aimed at strengthening the environmental attributes of several of its leading products.

![110765-tampa_verde[1] 540x231 100dpi](http://bestinpackaging.files.wordpress.com/2012/04/110765-tampa_verde1-540x231-100dpi.jpg?w=470)

Tetra Rex Pearl is a brand new packaging designed for premium milk and juice. Due for launch in the first quarter of 2013, Tetra Rex Pearl moves away from the faceted shapes traditionally associated with cartons to a more curvaceous simplistic shape. The curved, droplet-shaped keyline creates an impactful side profile and defines the overall new look. In addition, the absence of a front horizontal crease line creates one large front panel which not only opens up new branding possibilities, but also affords the space for a large, premium-looking closure.

Tetra Rex Pearl is a brand new packaging designed for premium milk and juice. Due for launch in the first quarter of 2013, Tetra Rex Pearl moves away from the faceted shapes traditionally associated with cartons to a more curvaceous simplistic shape. The curved, droplet-shaped keyline creates an impactful side profile and defines the overall new look. In addition, the absence of a front horizontal crease line creates one large front panel which not only opens up new branding possibilities, but also affords the space for a large, premium-looking closure.

The Tetra Pak A3/Flex platform for Tetra Gemina Aseptic offers the potential to produce three different shapes on the same machine and to switch between different shapes and sizes in the range, allowing customers to innovate rapidly in response to market demands.

The Tetra Pak A3/Flex platform for Tetra Gemina Aseptic offers the potential to produce three different shapes on the same machine and to switch between different shapes and sizes in the range, allowing customers to innovate rapidly in response to market demands.

To meet this demand, Tetra Pak launched Lokka, a new opening option for the Tetra Top Carton Shot in a convenient 100 ml package. Lokka is a new convenient tear-off opening which meets the demand for on-the-go consumption. Already available in Finland, Lokka can be applied to a range of products and delivers the convenience of a unique packaging at a competitive price. From an environmental perspective, the Tetra Top Carton Shot with Lokka opening offers the lowest CO2 level in the market.

To meet this demand, Tetra Pak launched Lokka, a new opening option for the Tetra Top Carton Shot in a convenient 100 ml package. Lokka is a new convenient tear-off opening which meets the demand for on-the-go consumption. Already available in Finland, Lokka can be applied to a range of products and delivers the convenience of a unique packaging at a competitive price. From an environmental perspective, the Tetra Top Carton Shot with Lokka opening offers the lowest CO2 level in the market.

You might remember that in a

You might remember that in a

Do you have an idea for better packaging? Go to the

Do you have an idea for better packaging? Go to the

At the Anuga various companies showed their developments in robots. For the food industry, however, it is not the robot that is of importance, that technique can be seen everywhere in whatever industry. Take the automotive industry as an example. For the food industry the robot-hands are of extremely importance and completely different from any other industrial application. Handling ‘naked’ product, like meat, cheese, chocolate etc, requires special robot-hands and fingers. We have seen several at the Anuga. I will write a separate article about recent developments in robot-hands. Here some photos from

At the Anuga various companies showed their developments in robots. For the food industry, however, it is not the robot that is of importance, that technique can be seen everywhere in whatever industry. Take the automotive industry as an example. For the food industry the robot-hands are of extremely importance and completely different from any other industrial application. Handling ‘naked’ product, like meat, cheese, chocolate etc, requires special robot-hands and fingers. We have seen several at the Anuga. I will write a separate article about recent developments in robot-hands. Here some photos from

In my second article about developments in pharmaceutical packaging (see my previous one about the

In my second article about developments in pharmaceutical packaging (see my previous one about the

It’s based on the oval or circular peel-off labels fixed to the skins of fruits, however the labels essentially dissolve into an organic soap mixture which can then be used as a cleaning product, partly aiding in the removal of substances from the fruit or vegetable’s surface.

It’s based on the oval or circular peel-off labels fixed to the skins of fruits, however the labels essentially dissolve into an organic soap mixture which can then be used as a cleaning product, partly aiding in the removal of substances from the fruit or vegetable’s surface.

As said in my previous article

As said in my previous article

Gourmet Trading Company

Gourmet Trading Company

The tetrahedral shape is well-known, particularly due to the introduction of the Tetra Pak tetrahedron, years ago. In flexible packaging it was used in the past because its truss structure is strong against crushing. With the original opening style of

The tetrahedral shape is well-known, particularly due to the introduction of the Tetra Pak tetrahedron, years ago. In flexible packaging it was used in the past because its truss structure is strong against crushing. With the original opening style of

This year the UK is in the spotlights of the world. First of all we have the Olympics and secondly, but not less important, it marks the Diamond Jubilee of Her Majesty Queen Elizabeth.

This year the UK is in the spotlights of the world. First of all we have the Olympics and secondly, but not less important, it marks the Diamond Jubilee of Her Majesty Queen Elizabeth.

Gordon & MacPhail, the Elgin based and family-run single malt specialist, has released just 85 bottles of

Gordon & MacPhail, the Elgin based and family-run single malt specialist, has released just 85 bottles of

In

In

The packaging is more compact than rigid jugs, and flattens when empty, which can provide easier disposal and lower waste-removal costs. When it comes to recyclability, the original rigid bottle is actually easier to recycle, as the Yes Pack may not be accepted for recycling in all areas. Kraft stated while the original rigid bottle is more accepted by recycling programs the recycling rate was low.

The packaging is more compact than rigid jugs, and flattens when empty, which can provide easier disposal and lower waste-removal costs. When it comes to recyclability, the original rigid bottle is actually easier to recycle, as the Yes Pack may not be accepted for recycling in all areas. Kraft stated while the original rigid bottle is more accepted by recycling programs the recycling rate was low.

Antistats are used widely in packaging such as film, thermoformed containers, and PET bottles, in which they help surfaces separate during production and reduce dust attraction for short-term cosmetic improvement.

Antistats are used widely in packaging such as film, thermoformed containers, and PET bottles, in which they help surfaces separate during production and reduce dust attraction for short-term cosmetic improvement. DuPont’s Entira Antistat IDP is based on an ethylene ionomer, which makes it compatible with polyolefins as well as other polymers like ABS and polystyrene. This compatibility results in transparency and a smooth surface for polyolefin packaging and blow moulded containers. Because it does not migrate, Entira AS does not interfere with film sealing properties.

DuPont’s Entira Antistat IDP is based on an ethylene ionomer, which makes it compatible with polyolefins as well as other polymers like ABS and polystyrene. This compatibility results in transparency and a smooth surface for polyolefin packaging and blow moulded containers. Because it does not migrate, Entira AS does not interfere with film sealing properties.